importance of hardness testing|how to measure hardness : solution Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. Resultado da Um KENO online zu spielen kann Ihnen die nachfolgende Tabelle dabei helfen, einen geeigneten Anbieter zu finden. Anbieter. Bewertung. Bearbeitungsgebühren. 4.5/5 - (1924 votes) Spielen ab 1,60 Euro. Gebühr: 0,60 Euro. 4.1/5 - (1603 votes) Spielen ab 1,50 Euro.

{plog:ftitle_list}

In this tutorial, you’ll learn how to use .sort_values() and .sort_index(), which will enable you to sort data efficiently in a DataFrame. By the end of this tutorial, you’ll know how to: Sort a pandas DataFrame by the values of one or more columns; Use the ascending parameter to change the sort order; Sort a DataFrame by its index using .

The hardness of a material enables it to resist bending, scratching or cutting. The most common tests are the Rockwell, Brinell, & Vickers hardness tests.Hardness Testing is applied to a great number of materials, and for over 250 years, it has been an invaluable and frequently used mechanical test. A variety of hardness tests can be used to establish the different hardness values for the .

Hardness testing is a fundamental process in manufacturing, essential for determining the properties and durability of materials. This testing helps manufacturers ensure that . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.Knowledge and insight into materialographic hardness testing – including how to test metallic and other materials, and the definitions, applications and conclusions of different hardness .Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond).

why is hardness important

Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing.Hardness testing holds paramount importance in materials engineering, essentially serving as the key to understanding a material's properties. It can determine the material's tensile .The Brinell Hardness Test is most typically used for testing materials that have an extremely coarse structure or when the surface is too rough for testing using another test method, such as castings and forgings.. Image Credit: Tinius .

Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing. It is important to ensure that hardness testing machines are maintained and calibrated so that correct readings can be obtained consistently over time. For Rockwell Hardness Testers, regular calibration with certified . Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other .Principally, the importance of hardness testing has to do with the relationship between hardness and other properties of material. For example, both the hardness test and the tensile test measure the resistance of a metal to plastic flow, and results of these tests may closely parallel each other. The hardness test is preferred because it is

Knoop Hardness Test: The Knoop hardness testing measures the hardness of small and delicate materials, thin sections, and coatings. These test methods employ a rhombic-based diamond probe. The elongated shape allows for a precise diamond-shaped indentation on small, narrow surfaces. HK = (1.854 × F) / (I2) HK is the Knoop hardness value Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. . There are important differences between nano hardness and traditional hardness: First of all, the two definitions are . Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness .

The hardness test for tablets is governed by multiple regulatory bodies, including the U.S. Pharmacopeia (USP), the European Pharmacopeia (EP), and other national and international organizations. They specify the standard procedures, acceptable ranges, and monitoring frequencies for hardness testing. . Why is tablet hardness important? Brinell Hardness Test: Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as .

Hardness testing is a crucial process used to determine the strength and durability of various materials.It involves measuring the resistance of a material to an indentation or deformation,which is then used to assess its mechanical properties.Hardness testing is used in various industries to ensure the quality and safety of their products.In this article,we will .

Hardness testing plays an important role in materials testing, quality control and acceptance of components. We depend on the data to verify the heat treatment, structural integrity, and quality of components to determine if a material has the properties necessary for its intended use. Establishing a correlation between the hardness result and .The ease with which the hardness test can be made has made it the most common method of inspection for metals and al-loys. Why so valuable? Principally, the importance of hardness testing has to do with the relationship between hardness and other properties of material. For example, both the hardness test and the tensile test measure the .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

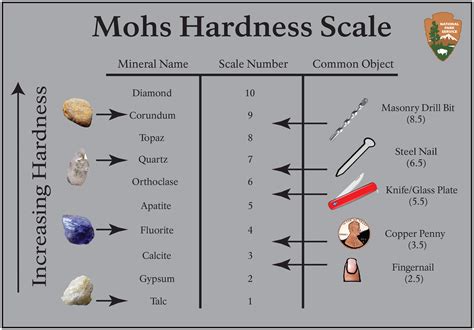

The importance of tablet hardness testing lies in its ability to: 1. Assessing Tablet Integrity. It helps ensure the mechanical strength and integrity of pharmaceutical tablets, allowing manufacturers to assess the tablets’ . Hardness testing is qualitatively and quantitatively discussed with particular references to the various types of hardness tests. Impact testing is also explained, including the mathematical relationship to calculate the impact energy. . Another important plasticity behavior is the shear modulus (G); which is explained in the following . Discover the critical role of rock hardness testing in geology and engineering. This article explores how assessing rock hardness aids in mineral classification, stability assessments, and resource exploration. Learn about the Mohs Hardness Scale, factors influencing hardness like mineral composition and texture, and why this knowledge is .ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .

In summary, hardness testing is an important aspect of ensuring the quality of metals and mechanical parts. By choosing the appropriate test method, considering the specific properties of the material being tested, and ensuring that the test equipment is properly calibrated and the test is performed by a trained and experienced operator .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, such as diamond cones and carbide balls. + 86 755 61301520; [email protected]; Search.The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. . It is important to keep the surface finish clean and decarburization from heat treatment should be removed.Importance and Applications. Hardness testing is crucial in sectors where material failure could lead to catastrophic outcomes, such as in aerospace, automotive, and construction. In manufacturing, ensuring the correct hardness means components can withstand the mechanical stresses they will encounter in use.

The Importance of Hardness Testing. Date posted December 16, 2021. Posted By: Tom Morrison in Community, What is hardness in metals? Hardness is the property of a material that allows it to resist permanent distortion, penetration, indentation, and scratching. Therefore, hardness is important from an engineering point of view because resistance .Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the information from a hardness test can be used to .

Mechanical Properties and Testing | Interview Question and Answers Tensile Test – Purpose , Graph , Results , Specimen Details Testing and Inspection Methods Of Welding Joints GATE 2018 Online Mock Test For Mechanical Students 22 Mechanical Properties Of Engineering Material GATE Mechanical Mock Test 2015 Stress-strain diagram for uniaxial . The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.

what is hardness testing machine

Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

types of hardness tester

struers hardness tester

windows 10 memory hard drive test

webTodas as reclamações para Códigos Lucrativos. Exibindo 10 de 569 reclamações (todas as reclamações ativas da empresa Códigos Lucrativos).

importance of hardness testing|how to measure hardness